Hauv kev lag luam tsim khoom, compressedCua Kom Qhuavyog tus txheej txheem tseem ceeb. Kev lag luam xws li kev lag luam precision, khoom noj / kws tshuaj, thiab hluav taws xob thov vaum tswj cov av noo tswj. Desiccant lub tshuab ziab khaub ncaws yog qhov ntsuas qhov kawg, muaj peev xwm txo cov lwg tseg ntawm cov cua compressed rau -40 ° C lossis qis dua. Nrog lawv cov qauv kev ua haujlwm hauv eco, kev ua haujlwm siab, thiab kev ua haujlwm tau yooj yim, cov tshuab ziab khaub ncaws no tau dhau los ua "txhua qhov kev lag luam kom qhuav.

Lub tsib lub koom haum tseem ceeb ntawm cov tshuab ziab khaub ncaws desiccant

1.Adsorption chaders: Dual-Ntauwd Cov Qauv Siv Kev Txhim Kho Kev Kawm Ntxiv Kev Ua Haujlwm Ntxiv rau kev ua haujlwm tsis muaj kev cuam tshuam.

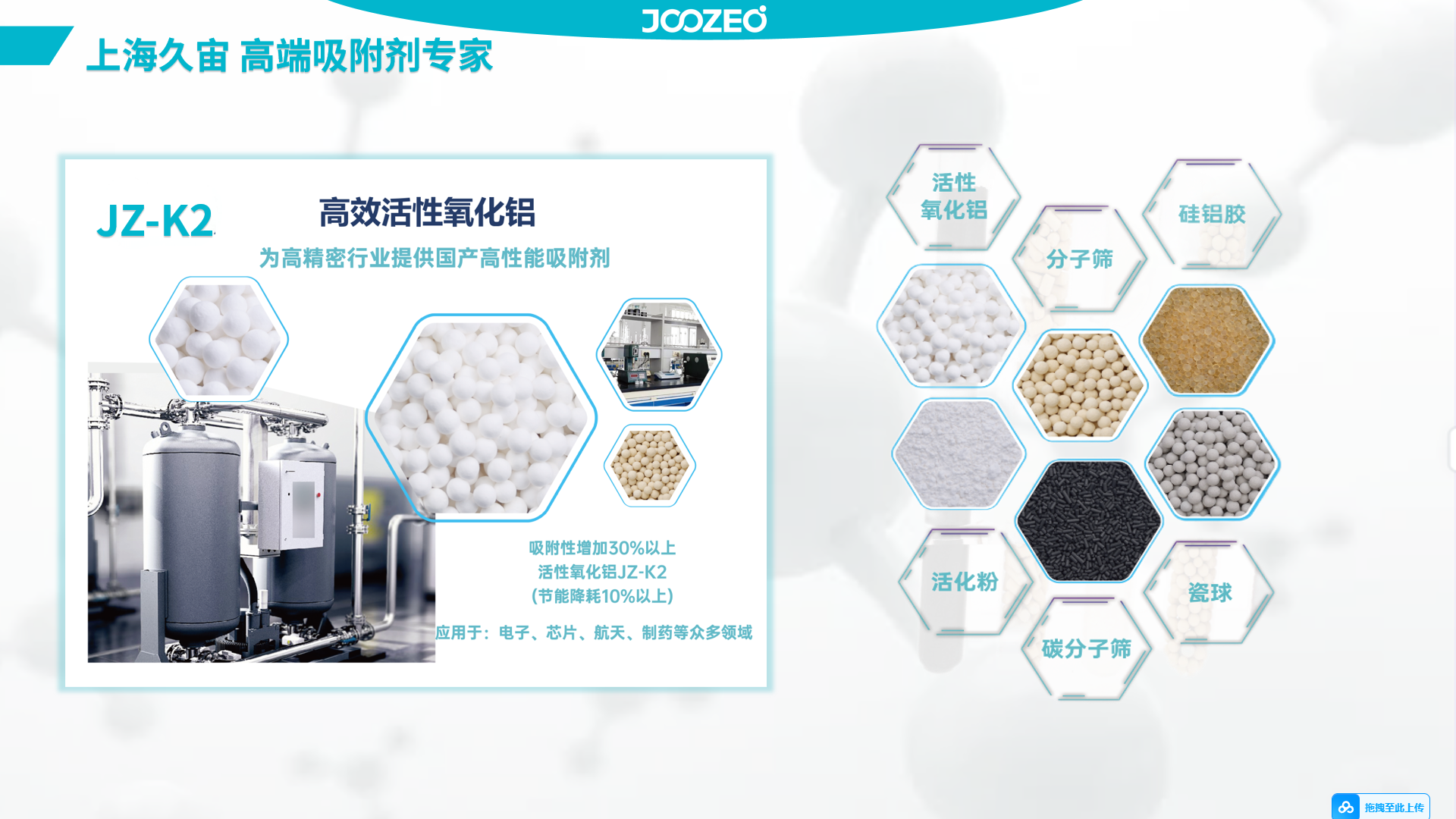

2.Adsorbents: Cov ntaub ntawv ua haujlwm siab zoo liQhib Aluminathiabmolecular siievesTxheeb xyuas cov dej noo ntxuav kom tshem tawm efficiency thiab kev pabcuam lub neej.

3.witching li qub: Pneumatic lossis Fais Txwv kom meej meej cov roj txaus tswj rau seamless kev hloov pauv ntawm adsorption thiab kev tsim dua tshiab.

4.regeneration system: Xws li cov roj regenation roj valve thiab rhaub kom tswj cov dej ntws thiab kub, ua kom rov qab ua tiav cov txiaj ntsig zoo.

5.Control system: Lub cajmeem ntse ua rau ntsuas kev hloov kho (piv txwv li, lub sijhawm ua tiav) rau kev ua tau zoo.

Workflow ntawm Desiccant Cov Tshuab Ziab Khaub Ncaws

1.Adousorption: Huab cua noo nkag mus rau hauv pej thuam adsorption, qhov twg adsorbent cuab ntxiab dej lwg dej, tso cua qhuav.

Nplooj ntawv 2.Cov qab hiav txwv: Cov adsorbents yog radenerated ntawm cov cua sov lossis ntxuav kom rov ua kom muaj peev xwm ua ntxiv.

3.YWitching: Dual yees lwm txoj haujlwm kom muaj kev ziab tas mus li.

Raws li muaj thev naus laus zis kev nce qib, cov ziab khaub ncaws desiccant txuas ntxiv mus evolve. Kev nrhav hauv cov ntaub ntawv adsorbent thiab tswj cov tshuab ntse txhim kho kev txuag hluav taws xob, ruaj khov, thiab kev hloov kho nruj siv cov kev lag luam nruj.

Lub Sijhawm Post: Feb-24-2025